Shipping Container Conversions 16ft pizza oven house

CS34402

Pricing

Call For Delivery Costs: 0800 061 2575

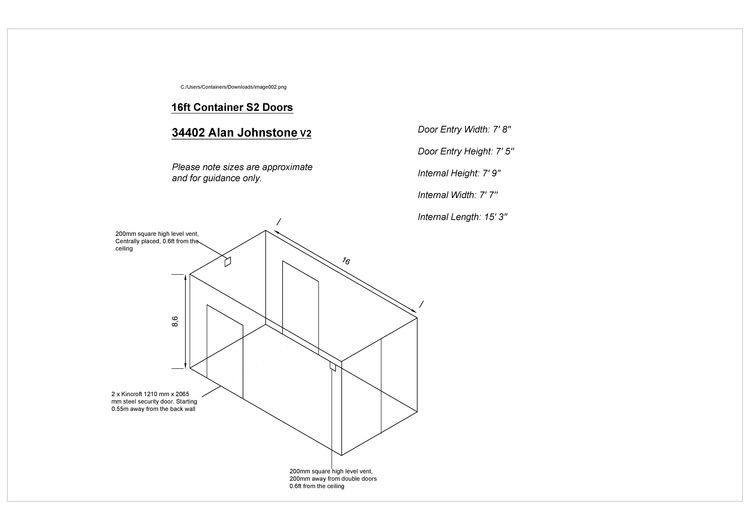

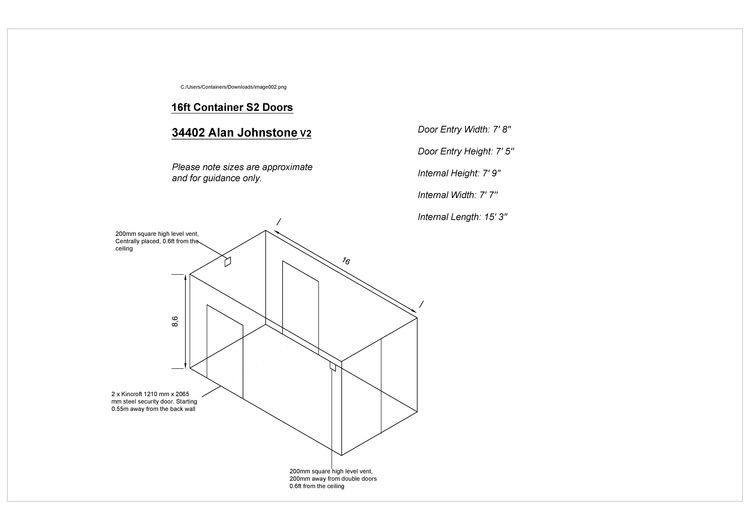

This conversion for the catering industry will house a wood-fired pizza oven. It will form part of a larger work space, whereby it will be attached on-site to another building, therefore we have extended a door frame for this purpose. The container will be placed on a sunken base to ensure a smooth transition between the two floors.

CD Code CS34402

As this container is a non standard length it has been cut down from a larger container, which means it requires a new end wall after the cut is made.

We also cut the apertures into the steel for the side doors. These doors are extra wide for disabled access, measuring 1.2m each. They are positioned on the long sides, opposite each other.

After delivery the container is going to attached to a pre-exisiting building on site, so we have created an extension of 100mm around one of the door frames, using box section steel.

After delivery the container is going to attached to a pre-exisiting building on site, so we have created an extension of 100mm around one of the door frames, using box section steel.

As the container is housing an oven, ventilation is essential. We cut two apertures and fitted frames to hold two high 200mm square vents, one in the end wall, and the other in the corner of the long side.

The inside of the container is insulated and lined with melamine, which is hygienic and easy to clean, therefore very well suited to areas involving food preparation. First we construct and fit a timber frame which will hold the insulating material, and then the melamine panels which will cover this. For more on this step read our article Melamine Lined Containers.

The container is repainted Jet Black, but to maintain the "factory finish" appearance, we mask the locking arms on the original doors while spraying. Read more about this step in our article Repainting New Containers

Features

Design

Special Features

- Original ISO container end doors

- Two disabled access side doors

- Extended door frame to attach to additional building

- Melamine lining

- Two 200mm square vents

- Repainted black

Step 1 - The steel work

New end wall and side doors

As this container is a non standard length it has been cut down from a larger container, which means it requires a new end wall after the cut is made.

We also cut the apertures into the steel for the side doors. These doors are extra wide for disabled access, measuring 1.2m each. They are positioned on the long sides, opposite each other.

Extended door frame

After delivery the container is going to attached to a pre-exisiting building on site, so we have created an extension of 100mm around one of the door frames, using box section steel.

After delivery the container is going to attached to a pre-exisiting building on site, so we have created an extension of 100mm around one of the door frames, using box section steel. The vents

As the container is housing an oven, ventilation is essential. We cut two apertures and fitted frames to hold two high 200mm square vents, one in the end wall, and the other in the corner of the long side.

Melamine lining and insulation

The inside of the container is insulated and lined with melamine, which is hygienic and easy to clean, therefore very well suited to areas involving food preparation. First we construct and fit a timber frame which will hold the insulating material, and then the melamine panels which will cover this. For more on this step read our article Melamine Lined Containers.

Repainting

The container is repainted Jet Black, but to maintain the "factory finish" appearance, we mask the locking arms on the original doors while spraying. Read more about this step in our article Repainting New Containers

The finished container

On-site

The container has been delivered, where it has been attached to the existing building, and the oven has been installed.

The CAD

As with any product, specification is subject to change without prior notification. You are advised to confirm current specification before buying.