Shipping Container Conversions 20ft ply lined with non slip floor plate

CS30307

Pricing

Call For Delivery Costs: 0800 061 2575

This conversion has been done for Herts Canoe Lifeguards, where wet equipment will be stored, so it was essential to bear these potentially wet conditions in mind when designing the layout. Therefore we used non slip steel flooring, exterior grade ply for the walls, and additional fuse ways for the electrics.

CD Code CS30307

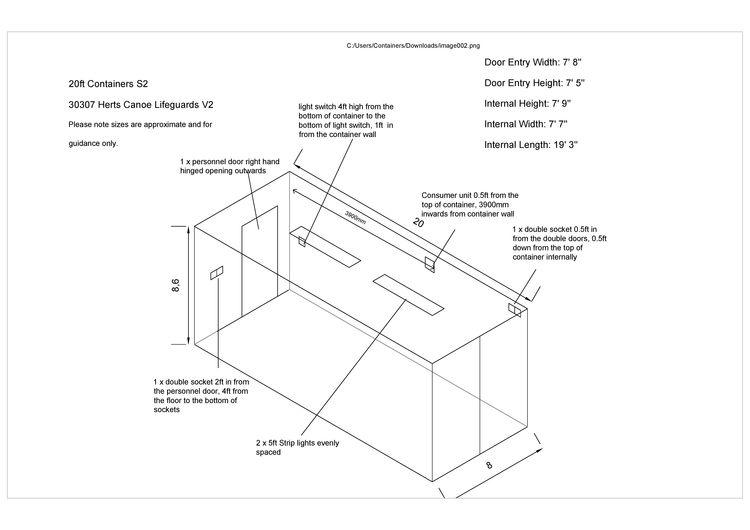

We begin with a used 20ft container (pictured below), which we modified with the following:

The container retains the set of original end doors, and we also fit a personnel door to the opposite end, for easy access and frequent use.

Durbar is a non-slip, raised pattern floor plate. As well as preventing slippage, it protects the timber floor of the container from spillages. The first task is to cut the durbar sheets to size on our guillotine. Then the plates are seam welded to the floor. On this job, we asked to extend the plate upwards, to underlap the ply lining when it's fitted, by 25mm.

The container is insulated and ply lined with exterior grade 12mm ply, which is suitable for conditions where the ply will be exposed to frequent wetting. The lining is fitted so it over laps the top of the steel floor plate, to ensure there is no gap between the two where water can enter.

The electrics include strip lights and sockets, and a consumer unit with two additional fuse ways, as seen below.

Features

Design

Conversion features

We begin with a used 20ft container (pictured below), which we modified with the following:

- S2 type original container doors with lockbox fitted

- Personnel door

- Ply lining and insulation

- Durbar steel flooring

- Electrics Package (consumer unit, 2 x 5ft strip lights, 2 x double sockets)

- Repainted Bottle Green

Personnel door

The container retains the set of original end doors, and we also fit a personnel door to the opposite end, for easy access and frequent use.

Repainted

Steel Flooring

Durbar is a non-slip, raised pattern floor plate. As well as preventing slippage, it protects the timber floor of the container from spillages. The first task is to cut the durbar sheets to size on our guillotine. Then the plates are seam welded to the floor. On this job, we asked to extend the plate upwards, to underlap the ply lining when it's fitted, by 25mm.

Ply lining and Electrics

The container is insulated and ply lined with exterior grade 12mm ply, which is suitable for conditions where the ply will be exposed to frequent wetting. The lining is fitted so it over laps the top of the steel floor plate, to ensure there is no gap between the two where water can enter.

The electrics include strip lights and sockets, and a consumer unit with two additional fuse ways, as seen below.

The finished container

Repainted Bottle Green

On site and fully operational

The CAD

As with any product, specification is subject to change without prior notification. You are advised to confirm current specification before buying.