Shipping Container Conversions 20ft extra wide side doors and ramp

CS27928

Pricing

Call For Delivery Costs: 0800 061 2575

CD Code CS27928

Our client, The University of West London, requested a used 20ft shipping container with extra wide side doors and a heavy duty ramp.

Before we begin work, we draw up plans to ensure all work is exactly as our client has requested.

This is achieved by taking a larger (40ft) container, cutting down from the end wall to a new length of 20ft, and then creating a new wall to fill the blank. For more details on this step, see our article Shipping Container Wall Build.

The first stage is to construct a framework for the new door and cut an aperture into container. The frame is then welded into the aperture and a drip rail welded to the top, so the new door can be attached. This door was fitted with an inside release, as a fire safety measure.

Features

Design

Special Features:

Our client, The University of West London, requested a used 20ft shipping container with extra wide side doors and a heavy duty ramp.

Other features include:

- No end doors

- Set of 6ft wide flat panel doors in the side

- Personnel door/fire door, with inside release

- Ply lined and insulated

- Steel ramp

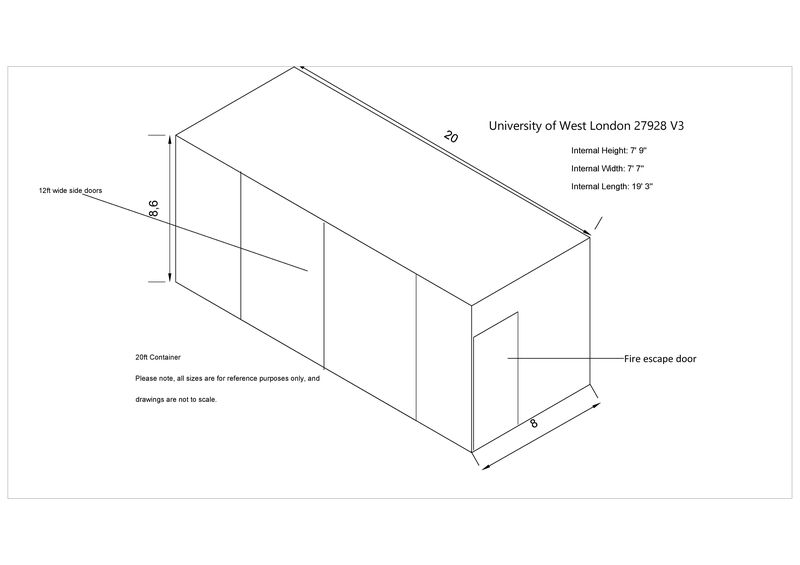

CAD drawing

Before we begin work, we draw up plans to ensure all work is exactly as our client has requested.

Step 1 - Producing a 20ft container without end doors

This is achieved by taking a larger (40ft) container, cutting down from the end wall to a new length of 20ft, and then creating a new wall to fill the blank. For more details on this step, see our article Shipping Container Wall Build.

Step 2 - Fitting the personnel/fire door

The first stage is to construct a framework for the new door and cut an aperture into container. The frame is then welded into the aperture and a drip rail welded to the top, so the new door can be attached. This door was fitted with an inside release, as a fire safety measure.

Step 3 - Fitting the side doors

Standard shipping container doors are a 4ft wide, making a total of width of 8ft for a pair, making them the perfect fit for the end of the container. However, with when the doors are fitted into the long side of the container, we can make them whatever width our client requires. The doors featured here give a total width of 12ft (6ft per door), making them ideal easy loading, or for extra wide items. They are also made from flat steel panels (S1 doors), which makes them far easier to handle than standard shipping container doors.

Step 4 - Ply lining and insulating

We used 12mm ply to line the whole interior, including the doors, with rock wool insulating material packed into the lining frame. For more on this step, please see our article Ply Lined Containers.

Step 5 - Repainting

Our client has chosen to have the container repainted in blue (RAL 5010).

Step 6 - Ramp

In conjunction with the extra wide storage doors, we fabricated a heavy duty steel ramp to make light work of loading/unloading. It has a Durbar anti-slip top plate.

As with any product, specification is subject to change without prior notification. You are advised to confirm current specification before buying.